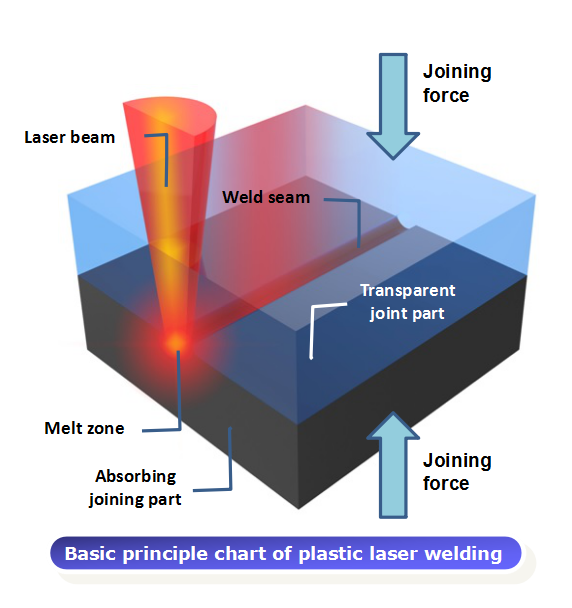

The commonly utilized laser welding form is called laser penetration welding. Firstly, pressure forces two plastic parts to join together. Then, a laser beam in the short-wave infrared region is placed onto the area to be welded. After passing through the upper transparent layer of the material, the lower layer takes in the laser beam. Once taken in, the laser energy is turned into heat energy. As the two layers of materials are forced together, the heat energy conducts from the absorbing layer to the transparent layer, making the two layers of materials melt and connect. Simultaneously, the thermal expansion of the material brings about internal pressure. Thus, the combined effect of the internal and external pressure makes sure that the two parts are firmly welded. For the product where the lower-layer material does not absorb the laser, an absorbent needs to be added to the lower layer.

Laser Plastic Welding Types

Clear Material Laser Welding

Welcome to inquire about SMART Laser, you can send us an email, or call us!

zxjnlaser SMART

zxjnlaser SMART